Mastering the SAP Manufacturing unit Calendar: A Complete Information to T-Codes and Performance

Associated Articles: Mastering the SAP Manufacturing unit Calendar: A Complete Information to T-Codes and Performance

Introduction

With enthusiasm, let’s navigate by the intriguing matter associated to Mastering the SAP Manufacturing unit Calendar: A Complete Information to T-Codes and Performance. Let’s weave attention-grabbing data and provide recent views to the readers.

Desk of Content material

Mastering the SAP Manufacturing unit Calendar: A Complete Information to T-Codes and Performance

The manufacturing unit calendar in SAP is an important ingredient for planning and controlling manufacturing. It defines the working and non-working days for a particular plant or location, impacting numerous points of producing, from capability planning and scheduling to costing and reporting. Understanding its intricacies and the related SAP transaction codes (T-codes) is important for any manufacturing group using SAP. This text supplies a complete overview of the SAP manufacturing unit calendar, exploring its performance, related T-codes, and finest practices for efficient administration.

Understanding the Basis: What’s a Manufacturing unit Calendar?

A manufacturing unit calendar in SAP is a grasp knowledge object that specifies the working and non-working days for a selected plant. This calendar is not merely a listing of holidays; it encompasses all points of a plant’s operational availability. It considers elements similar to:

- Holidays: Nationwide, regional, and company-specific holidays.

- Weekends: Defining the usual working days of the week.

- Shift patterns: Accounting for a number of shifts and their various working hours.

- Deliberate downtime: Scheduled upkeep, coaching, or different deliberate interruptions to manufacturing.

- Particular working days: Days with altered working hours or particular manufacturing constraints.

The accuracy and completeness of the manufacturing unit calendar immediately affect the reliability of manufacturing planning, scheduling, and costing. An inaccurate calendar can result in inaccurate capability calculations, missed deadlines, and flawed value estimations.

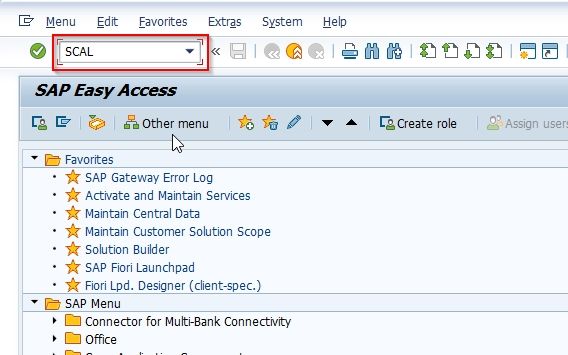

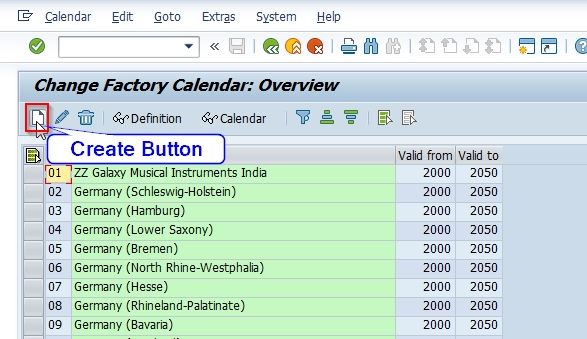

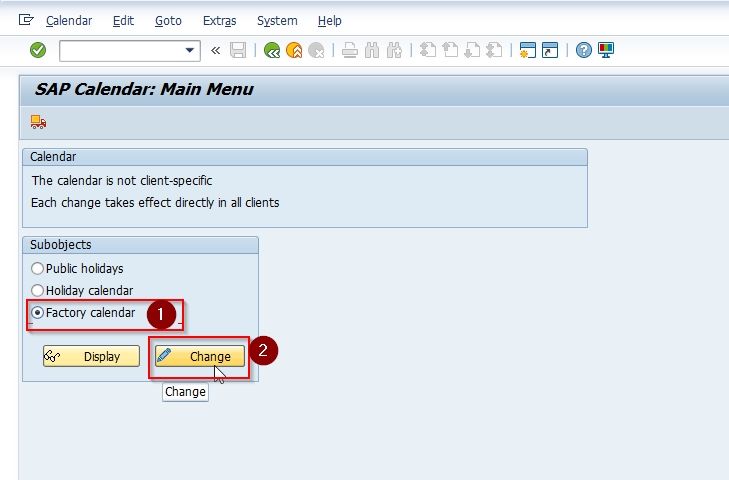

Key SAP T-Codes for Manufacturing unit Calendar Administration:

A number of SAP T-codes are used to handle and work together with manufacturing unit calendars. Crucial ones embrace:

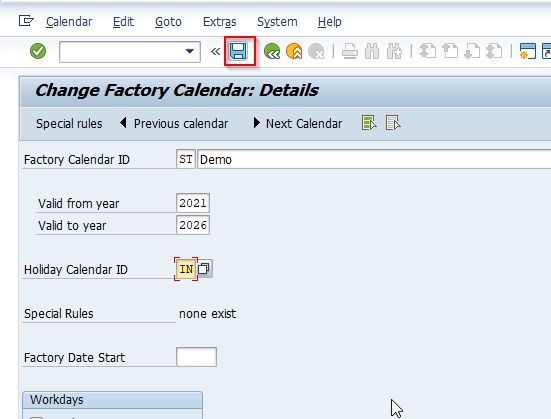

-

OP01 (Create Calendar): This T-code is used to create new manufacturing unit calendars. It permits defining the calendar’s title, plant project, and the precise working and non-working days. Customers outline the calendar’s parameters, together with the beginning and finish dates, and specify particular person days or ranges of days as working or non-working.

-

OP02 (Change Calendar): This T-code permits modifications to an current manufacturing unit calendar. Modifications may be made to working days, holidays, and different parameters. Cautious consideration should be paid when making modifications, particularly if the calendar is already utilized in manufacturing planning. Applicable authorization ranges are essential to stop unintended modifications.

-

OP03 (Show Calendar): This T-code supplies a read-only view of a particular manufacturing unit calendar. It is helpful for reviewing the calendar’s particulars, verifying its accuracy, and understanding its construction earlier than making any modifications. This T-code is especially useful for auditing functions and making certain knowledge integrity.

-

OP04 (Copy Calendar): This T-code permits creating a replica of an current manufacturing unit calendar. That is helpful for creating a brand new calendar primarily based on an analogous current one, decreasing the trouble of making a brand new calendar from scratch. That is notably useful when creating calendars for various crops with related operational traits.

-

OP05 (Delete Calendar): This T-code permits the deletion of a manufacturing unit calendar. Nonetheless, warning needs to be exercised as deleting a calendar that’s presently assigned to a plant can disrupt manufacturing planning and scheduling. The system usually performs checks to make sure that the calendar just isn’t in use earlier than permitting deletion.

-

OPUR (Preserve Calendar for Vacation Administration): This T-code is particularly for sustaining holidays. It permits the creation, modification, and deletion of vacation entries for particular dates and areas. This simplifies the method of updating the manufacturing unit calendar with related vacation data.

Integrating the Manufacturing unit Calendar into Manufacturing Planning:

The manufacturing unit calendar performs a significant position in numerous manufacturing planning processes. Its knowledge is built-in into a number of modules and processes inside SAP:

-

Capability Planning: The calendar defines the accessible capability for every manufacturing useful resource. Correct capability planning depends closely on the calendar’s correct illustration of working and non-working days.

-

Manufacturing Scheduling: The calendar influences the creation and optimization of manufacturing schedules. The system considers the calendar’s availability when scheduling manufacturing orders, making certain that orders are scheduled solely throughout accessible working hours.

-

Materials Necessities Planning (MRP): The calendar impacts the calculation of fabric necessities. The system considers the calendar’s working days when figuring out the timing of fabric procurement and manufacturing.

-

Costing: The calendar influences value calculations. The variety of working days impacts the calculation of overhead prices and different value parts.

Greatest Practices for Manufacturing unit Calendar Administration:

Efficient administration of the manufacturing unit calendar requires a structured strategy and adherence to finest practices:

-

Common Evaluation and Updates: The calendar needs to be reviewed and up to date usually to mirror modifications in working days, holidays, and deliberate downtime.

-

Centralized Administration: Assign duty for calendar administration to a particular workforce or particular person to make sure consistency and accuracy.

-

Model Management: Preserve completely different variations of the calendar for various situations or planning horizons.

-

Correct Documentation: Doc all modifications made to the calendar, together with the rationale for the modifications and the date of implementation.

-

Consumer Coaching: Present enough coaching to customers on the right way to use the manufacturing unit calendar and the related T-codes.

-

Knowledge Validation: Frequently validate the calendar knowledge to make sure its accuracy and consistency.

Troubleshooting Widespread Points:

A number of points can come up when working with manufacturing unit calendars. Understanding these widespread issues and their options is important:

-

Calendar not assigned to a plant: Be sure that the calendar is appropriately assigned to the related plant utilizing transaction code OP01.

-

Inconsistent calendar knowledge: Frequently assessment and reconcile the calendar knowledge to make sure consistency and accuracy.

-

Surprising downtime: Replace the calendar to mirror any surprising downtime, similar to unplanned upkeep or unexpected occasions.

-

Incorrect vacation entries: Confirm the accuracy of vacation entries utilizing transaction code OPUR.

Conclusion:

The manufacturing unit calendar in SAP is a elementary element of manufacturing planning and management. Its accuracy and completeness are paramount for environment friendly manufacturing operations. By understanding the performance of the varied T-codes, integrating the calendar successfully into manufacturing processes, and adhering to finest practices, organizations can leverage the facility of the SAP manufacturing unit calendar to optimize their manufacturing operations and obtain better effectivity and profitability. Proactive administration, common assessment, and meticulous knowledge upkeep are key to maximizing the advantages of this important SAP device. By means of cautious planning and implementation, organizations can guarantee their manufacturing unit calendar stays a dependable and correct basis for all their production-related actions.

/userfiles/images/fc-5.jpg)

/userfiles/images/fc.jpg)

/userfiles/images/fc-3.jpg)

/userfiles/images/fc-8.jpg)

Closure

Thus, we hope this text has offered helpful insights into Mastering the SAP Manufacturing unit Calendar: A Complete Information to T-Codes and Performance. We hope you discover this text informative and useful. See you in our subsequent article!